You know that feeling when you’re staring at a seemingly simple problem, like filtering debris from a liquid, sorting different grades of material, or just needing to separate this from that? It looks straightforward until you dive in and realize the sheer number of variables at play. The heart of so many of these industrial and even creative processes isn’t some complex, digitally-driven marvel, it’s something far more fundamental, far more tactile. It’s a sheet of metal, steadfast and unassuming, but riddled with a precise pattern of holes. This is the world of perforated sheets, and your entire operation’s efficiency can hinge on this single choice. It’s not just about picking a material with holes, it’s about engineering a solution that breathes, filters, screens, and separates with exacting precision. And where does this journey begin? It begins with a conversation with a knowledgeable perforated sheet manufacturer. This isn’t a purchase you rush. This is a partnership you form.

The Unsung Hero: More Than Just a Hole-y Sheet

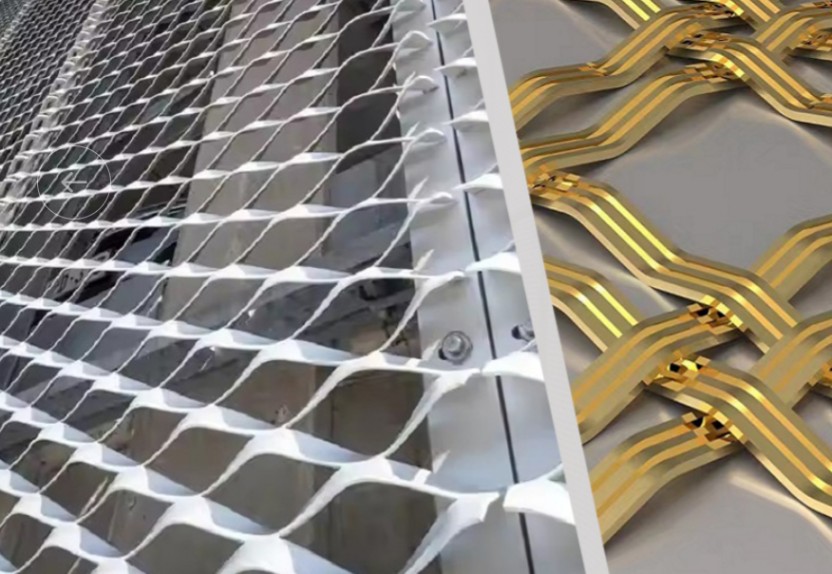

Let’s get one thing straight right off the bat. A perforated sheet is not the same as wire mesh or an expanded metal sheet. It starts its life as a solid, flat sheet—cold-rolled steel, stainless steel, aluminum, you name it—and then, through a variety of sophisticated processes, it gets punctured with a deliberate, repeating pattern of holes. This method of creation is what gives it its unique strength and rigidity. Unlike mesh, which is woven, a perforated sheet maintains the structural integrity of the original material, just with strategically removed sections. This makes it incredibly versatile. It can be the sturdy platform you walk on, the elegant façade of a building, the sieve that sorts millions of tons of aggregate, or the filter that ensures the purity of a chemical solution. The magic lies in the details, in the three fundamental characteristics that you and your perforated sheet manufacturer will obsess over: the pattern of the holes, the size of the holes, and the amount of open area. These three elements are the holy trinity of perforation, and getting their interplay right is what separates a successful application from a costly failure.

Think of the pattern as the personality of the sheet. A round hole pattern is the classic, the workhorse, offering excellent flow-through and a clean, simple aesthetic. But then you have square holes, which provide a larger open area for their size, perfect for screening and sizing applications where you need maximum throughput. Slotted holes, on the other hand, are the directional experts. They’re fantastic for de-watering, filtering, or applications where you want material to flow in one direction but not others. And this is just scratching the surface. A creative perforated sheet manufacturer will have a portfolio of patterns: hexagonal, decorative, custom designs—each imparting a different functional and visual characteristic to the sheet. The pattern isn’t just an aesthetic choice, it dictates how material interacts with the sheet, how it flows through, around, or across it. It affects the strength of the sheet and, crucially, the clarity of the “aperture” or the sharpness of the hole’s edge, which is vital for precise screening.

It All Starts with the Material: The Backbone of Your Project

You wouldn’t build a boat out of paper, and you wouldn’t screen abrasive rock with a delicate aluminum sheet. The choice of material is the very first and perhaps most critical decision you’ll make, as it defines the sheet’s soul—its strength, its durability, its resistance to the elements, and its very lifespan. This is where the expertise of your perforated sheet manufacturer becomes invaluable. They aren’t just order-takers, they’re material scientists in their own right, guiding you away from potential pitfalls.

Take stainless steel, for instance. It’s the champion of champions for a reason. When your filtration or screening needs involve moisture, chemicals, high temperatures, or a requirement for strict hygiene, stainless steel is often the undisputed king. Grades like 304 and 316 offer fantastic corrosion resistance, with 316 providing extra protection against chlorides, making it ideal for marine environments or chemical processing plants. It’s strong, it’s durable, and it can be cleaned and sterilized with ease, which is why it’s the go-to for food and beverage, pharmaceutical, and medical applications. A perforated sheet manufacturer with a strong inventory will have various stainless grades on hand, ready to be transformed into your specific solution.

But what if your primary concern is weight or cost, and the environment isn’t particularly harsh? Enter aluminum. Lightweight, naturally corrosion-resistant, and possessing a great strength-to-weight ratio, aluminum perforated sheets are perfect for architectural screens, grilles, lighter-duty filtration, and applications where every kilogram counts. It’s easier to handle and install, and it can be anodized or powder-coated in a rainbow of colors for aesthetic appeal. Then there’s carbon steel, the rugged, no-nonsense option. When you need raw, brute strength and abrasion resistance for heavy-duty screening of materials like mined ores, aggregates, or coal, carbon steel is your best bet. It’s less resistant to rust, so it might require painting or galvanizing, but for sheer toughness in dry environments, it’s hard to beat. A savvy perforated sheet manufacturer will help you navigate this landscape, asking the right questions about your operating environment, the materials you’re processing, and the physical stresses the sheet will endure to steer you toward the perfect material match.

The Geometry of Separation: Hole Size, Pattern, and Open Area

This is where the engineering truly comes to life. You’ve chosen your material—the what. Now it’s time to define the how: the precise geometry of the perforations. This triad of hole size, pattern, and open area is a delicate dance, and changing one element inevitably affects the others. It’s the core of the customization process with your perforated sheet manufacturer.

Hole size, or aperture, is often the first specification people think of. It seems simple: if you want to filter out particles larger than 1mm, you need holes smaller than 1mm, right? Well, yes, but it’s not always that linear. You also have to consider the “blinding” effect, where particles can get stuck in the holes, clogging the sheet. Sometimes, a slightly larger hole with a different pattern can be more effective than a smaller, more prone-to-clogging one. The hole size is directly tied to the separation or filtration grade. In screening, for example, it determines the cut point—the size at which particles are either retained or passed through.

But hole size doesn’t exist in a vacuum. It’s intimately connected to the pattern. As mentioned, a round hole pattern is standard, but a square hole pattern offers more open area for the same hole size. This means more material can pass through more quickly, increasing throughput. However, square holes might not be as strong as round holes in certain applications, as the corners can be points of stress concentration. Slotted holes, with their long, narrow openings, are perfect for allowing flat or fibrous materials to pass through while blocking more spherical particles. The pattern also affects the “bridge”—the solid material between the holes. A wider bridge means a stronger, more durable sheet but less open area. A narrower bridge maximizes open area but can sacrifice some structural integrity. This is a key discussion point with your perforated sheet manufacturer.

And this brings us to open area, the total percentage of the sheet’s surface that is made up of holes. It’s a critical performance metric. A higher open area generally means better flow rates, whether you’re dealing with liquids, gases, or dry materials. It reduces pressure drop across the sheet and can improve efficiency. However, a higher open area often means less material, which can compromise strength. Calculating the perfect balance is key. Your perforated sheet manufacturer uses precise formulas to determine the open area based on your chosen hole size, pattern, and bridge dimensions, ensuring the final product performs exactly as your application demands. This isn’t guesswork, it’s applied mathematics and physics, all aimed at achieving your specific goal.

The Manufacturing Muscle: How a Perforated Sheet is Born

Understanding how these sheets are made isn’t just academic, it gives you insight into the limitations and possibilities of your design. There are two primary methods, and the choice between them can impact the quality, precision, and cost of your final product. A top-tier perforated sheet manufacturer will often be proficient in both and will recommend the best process for your job.

The traditional workhorse is rotary perforating. Imagine a massive, cylindrical punch press. The sheet metal is fed through the machine, and a rotating drum studded with hardened steel punches descends, punching holes in rapid succession as the sheet moves through. This is a high-speed, continuous process, making it incredibly efficient and cost-effective for long runs of standard patterns, especially round holes. It’s perfect for producing large volumes of screening material for the mining or agricultural industries. However, it can have limitations with very thick materials or highly complex, custom patterns.

For the ultimate in precision and flexibility, there’s CNC (Computer Numerical Control) punching. This is where the art of perforation meets digital precision. A flat sheet is secured on a massive bed, and a single punching tool, guided by a computer program, moves across the sheet, punching holes one at a time according to a digital blueprint. The tool can be changed automatically from a library of hundreds of different punch-and-die sets, allowing for incredibly complex and custom patterns within the same sheet. Want to mix round and square holes? No problem. Need a decorative logo perforated into the center of an industrial screen? CNC punching makes it possible. It’s the go-to method for architectural projects, custom filters, and any application where the pattern is non-standard or requires extreme accuracy. When you’re working with a perforated sheet manufacturer on a bespoke project, you’re almost certainly leveraging the power of CNC technology. The choice of method impacts the burr—the slight raised edge on the underside of the hole. A good manufacturer will control and, if specified, minimize this burr to ensure smooth material flow and safety.

The Finishing Touches: It‘s Not Over After the Punching

The journey of a perforated sheet doesn’t end the moment the last hole is punched. The finishing processes applied can dramatically alter its performance, lifespan, and appearance. This is another area where your collaboration with the perforated sheet manufacturer is crucial. Discussing the end-use environment will determine what, if any, finishing steps are required.

For many stainless steel and aluminum sheets, the standard mill finish might be perfectly adequate. But if the sheet will be handled frequently, or if the application requires a smooth surface for easy cleaning and material flow, deburring is essential. This process removes the small, sharp edges left by the punching process, creating a safer, smoother product. For architectural applications, the finish is everything. Perforated sheets can be polished to a mirror shine, brushed for a satin look, or even color-coated through powder coating or anodizing (for aluminum). Powder coating is particularly popular as it provides a durable, wear-resistant, and colorful finish that can withstand outdoor exposure, making perforated sheets a favorite for building facades, sunscreens, and interior design elements.

For carbon steel, finishing is often about protection. Since carbon steel is susceptible to rust, applying a protective coating is vital for longevity in any non-dry environment. Galvanizing, which involves coating the sheet in a layer of zinc, is a common and highly effective method. The sheet can be galvanized after perforation (post-perf galvanizing), ensuring the holes themselves are also protected. Alternatively, it can be painted or coated with other protective polymers. A reliable perforated sheet manufacturer will offer these value-added services, transforming a raw, perforated blank into a finished, application-ready component. It’s this end-to-end capability that turns a simple supplier into a true solutions provider.

Real-World Scenarios: Putting It All Together

Let’s move from theory to practice. Imagine you’re setting up a system to sort different grades of gravel. Your primary concerns are abrasion resistance, high throughput, and precise sizing. You’d likely be guided towards a thick carbon steel perforated sheet with a round or square hole pattern. The carbon steel can handle the brutal abrasion of the rock, and the hole size would be carefully calculated to achieve your desired separation, say, 1/2-inch gravel from 1-inch gravel. The open area would be maximized within strength constraints to allow tons of material to pass through efficiently. Your perforated sheet manufacturer would ensure the bridges are wide enough to prevent premature failure from the constant impact.

Now, flip the script. You’re an architect designing a breathtaking, ventilated facade for a new museum. Here, the priorities shift to aesthetics, weather resistance, and perhaps even creating specific light and shadow patterns inside the building. You’d be working with a stainless steel or aluminum sheet, likely with a custom, decorative pattern punched via CNC. The material choice ensures it won’t rust and will maintain its beauty for decades. The finish might be a custom powder-coated color, and the open area calculation would balance visual privacy with the need for airflow and daylight penetration. In this scenario, the perforated sheet manufacturer acts as a fabricator, turning an artistic vision into a buildable reality.

Or consider a high-stakes pharmaceutical application where you’re filtering a valuable active ingredient. The demands are for absolute hygiene, no contamination, and the ability to be sterilized repeatedly. An electropolished 316 stainless steel perforated sheet would be the choice. Electropolishing creates an ultra-smooth, microscopically even surface that prevents bacteria from adhering and makes cleaning a breeze. The hole size would be exacting, measured in microns, to ensure no oversized particles contaminate the final product. In this case, the perforated sheet manufacturer isn’t just making a filter, they’re contributing to a critical step in a life-saving production line.

Your Partner in Precision: Making the Final Choice

So, how do you actually go about choosing the right perforated sheet? It starts not with a catalog, but with a set of questions. You need to become an internal detective for your own project. What material are you processing? Is it wet, dry, corrosive, abrasive, hot? What is the particle size distribution? What throughput do you need? What are the pressure and load conditions? What are the environmental factors—indoors, outdoors, saline atmosphere? What are your hygiene requirements? What is your budget?

Armed with these answers, you then seek out a perforated sheet manufacturer who acts as a consultant. Look for one with a strong technical team, a diverse portfolio of materials and capabilities, and a willingness to ask as many questions as they answer. The right partner will listen to your needs and might even suggest alternatives you hadn’t considered—a different pattern that increases efficiency, a material grade that offers longer life for a marginally higher cost, or a finishing treatment that solves a hidden problem.

The world of perforated sheets is a testament to the idea that simplicity of concept can yield immense complexity in application. That humble sheet of metal, transformed by a pattern of holes, becomes a critical tool in industries that shape our world. From the food we eat to the energy we use, from the buildings we inhabit to the medicines that heal us, perforated sheets are there, working silently in the background. Choosing the right one isn’t a minor procurement task, it’s a design and engineering decision with profound consequences. By understanding the interplay of material, geometry, and manufacture, and by partnering with a skilled perforated sheet manufacturer, you transform a basic component into a bespoke engine of efficiency, a perfect solution tailored precisely to your filtration, screening, or separation needs. Don’t just buy a perforated sheet, engineer a solution.

More Stories

Quick Loan App Guide for Fast Digital Borrowing Easy Access

What Happens After You Open a Demat Account Online

Stock Investing Basics for Long-Term Financial Planning